Uncategorized

ARIX Technology at the Cutting Edge

With ARIX, the diamonds are perfectly uniform and aligned. Diamond Products has the sole South African agency for this globally renowned innovation. With standard diamond cutting blades available in the market, the norm is for the diamonds to be randomly distributed. This causes what’s termed as clustering – some diamonds are closer together, and others with spaces, which makes for inefficient cutting.

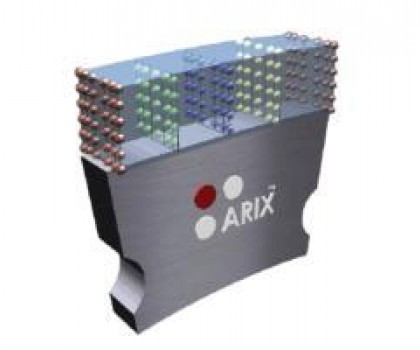

Getting perfectly even diamond distribution has always been a challenge for any diamond tool maker, but with ARIX this is easily achieved. A balanced load per diamond (every diamond working evenly), which translates into a excellent balance of concentration (and cost). In simple terms; good alignment equals excellent cutting efficiency.

During the ARIX manufacturing process, diamonds are placed in three dimensional patterns, which can be varied to either offer a narrow or more widely spaced pattern, depending on the cutting task.

ARIX is faster, more stable and sustainable. Plus from an environmental point of view, is the silent centre of the ARIX blade as opposed to the standard centres.